Precise Measurement

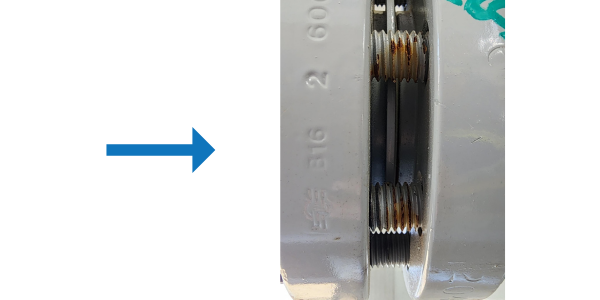

In oil and gas and construction, it is not uncommon to encounter instances where operations overlook the installation of a flow conditioner or fail to understand its purpose. We see this quite frequently from fabricators and construction not knowing what a flow conditioner is or why it needs to be installed.

Meter runs play a crucial role in accurately measuring fluid flow, particularly in industries such as oil and gas, where precise measurements are essential for process control and regulatory compliance.

The Flow Conditioner

One important component of a meter run is the flow conditioner, which ensures that the flow entering the meter is well-conditioned and free from disturbances. Flow conditioners are specially designed devices that pre-condition the flow of fluid before it reaches the meter. The purpose of a flow conditioner is to eliminate or minimize any disturbances in the fluid flow, such as turbulence, swirls, or irregularities. This ensures a smooth, uniform flow profile that allows for accurate and reliable metering.

So in conclusion, the installation of a flow conditioner in a meter run is crucial for accurate and reliable flow measurement and Blue Chip can help spot the gap so that corrective actions can be taken, to help you do it right.

AGA 2000-Compliant

Part of being an AGA 2000-compliant meter run means that a flow conditioner will be utilized, which is not the case since the construction company didn’t see the need to install the flow conditioner. Without the flow conditioner in place, the meter does not meet the AGA specifications or measurement uncertainty. This can have numerous negative consequences for both the company and its customers. This includes inaccurate readings, which can lead to financial losses for the company and an inability to properly regulate the gas flow. Moreover, the absence of a flow conditioner can result in issues with downstream equipment and processes. Therefore, it is of utmost importance to ensure that all components of the meter run, including the flow conditioner, are properly installed and maintained.

AGA 2000 compliant means that the meter run meets the standards set forth by the American Gas Association in their AGA 2000 Report No. 3, which provides guidelines for the design and installation of orifice meters for natural gas flow measurement.

If you need help or direction to make sure your measurement, or environmental reporting practices are equitable and compliant, we can help you do it right.

If you’re interested in learning more on this topic, with additional questions or discussions, please send us an email info@bluechipmrc.com

Know someone who might be interested in this newsletter? Share it with them!